What are metal surface treatment agents?

Metal surface treatment agent refers to the chemical agents used to treat metal surface. Metal surface treatment includes matrix pretreatment such as degreasing, rust removal, phosphating and rust prevention. It is prepared for metal coating technology and metal protection technology. The quality of matrix pretreatment has a great influence on the preparation of coating and the use of metal. sodium tripolyphosphate is very effective in removing oil and dirt from metal surface. What is sodium tripolyphosphate?

Sodium tripolyphosphate, nicknamed pentasodium phosphate, is a white powder or granular solid. It can dissolve in water, complex alkali metal with metal salt, soften water, adjust and buffer the PH value of saponification value, 1% solution PH value is 9.7, and has the ability of ion exchange. It is mainly used as water treatment agent and additive in synthetic detergent.

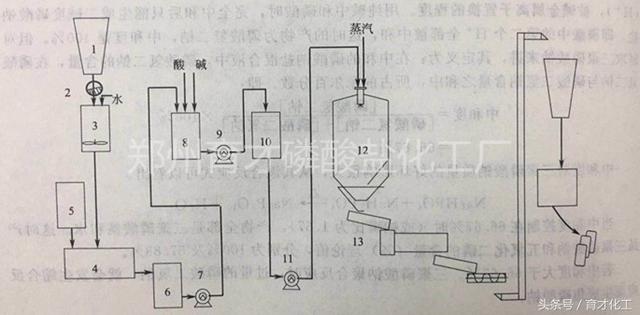

One-step production process of sodium tripolyphosphate by empty pyrolysis tower of phosphoric acid:

The soda in the soda bin (1) is metered by a metering device (2), and then fed into a soda slurry preparation tank (3) with an agitator. At the same time, the measured water is added to the tank to produce about 50% of the soda suspension solution. The soda suspension solution is fed into the neutralizer (4) by potential difference. Phosphoric acid is sent from the phosphoric acid plant to the phosphoric acid storage tank (5) for storage. It still uses the potential difference to flow out and then enters the neutralizer through the flow regulator. In the reactor, phosphoric acid reacts with soda to form orthophosphate solution (hereinafter referred to as neutralizing solution) which flows into the neutralizing buffer tank (6). The neutralizing liquid is extracted from the buffer tank by a pump (7) and pumped into the adjustment tank (8). In the adjusting tank, the neutralizing liquid is adjusted to the required neutralization degree with phosphoric acid or soda ash, and the adjusted neutralizing liquid pump (9) is put into the spray tank (10) for reserve. The neutralizing liquid in the spray tank is pumped out by a pump (11) and injected into a powder spray tower (12). In the powder spray tower, the neutralizing liquid is dried by one step method and condensed to form sodium tripolyphosphate. Sodium tripolyphosphate is sent from the bottom of the spray tower to the cooling drum for cooling by vibrating feeder (13). The cooled sodium tripolyphosphate is screened by vibrating screen and then fed by screw conveyor to bucket elevator and lifted to sodium tripolyphosphate silo. The finished product is packed with sodium tripolyphosphate in silo.

The soda in the soda bin (1) is metered by a metering device (2), and then fed into a soda slurry preparation tank (3) with an agitator. At the same time, the measured water is added to the tank to produce about 50% of the soda suspension solution. The soda suspension solution is fed into the neutralizer (4) by potential difference. Phosphoric acid is sent from the phosphoric acid plant to the phosphoric acid storage tank (5) for storage. It still uses the potential difference to flow out and then enters the neutralizer through the flow regulator. In the reactor, phosphoric acid reacts with soda to form orthophosphate solution (hereinafter referred to as neutralizing solution) which flows into the neutralizing buffer tank (6). The neutralizing liquid is extracted from the buffer tank by a pump (7) and pumped into the adjustment tank (8). In the adjusting tank, the neutralizing liquid is adjusted to the required neutralization degree with phosphoric acid or soda ash, and the adjusted neutralizing liquid pump (9) is put into the spray tank (10) for reserve. The neutralizing liquid in the spray tank is pumped out by a pump (11) and injected into a powder spray tower (12). In the powder spray tower, the neutralizing liquid is dried by one step method and condensed to form sodium tripolyphosphate. Sodium tripolyphosphate is sent from the bottom of the spray tower to the cooling drum for cooling by vibrating feeder (13). The cooled sodium tripolyphosphate is screened by vibrating screen and then fed by screw conveyor to bucket elevator and lifted to sodium tripolyphosphate silo. The finished product is packed with sodium tripolyphosphate in silo.

Yucai Phosphate Chemical Plant specializes in producing: sodium hexametaphosphate, sodium pyrophosphate, sodium tripolyphosphate, sodium hydrogen phosphate, industrial phosphoric acid, trisodium phosphate, aluminum dihydrogen phosphate, solid aluminum dihydrogen phosphate, liquid aluminum dihydrogen phosphate, sodium dihydrogen phosphate and other phosphate series products after more than 30 years of continuous pursuit and development, relying on skilled chemical technology and product development, equipment updating and many universities. Established a good cooperative and sharing relationship, in the chemical industry played a (Yucai phosphate) brand!

Contact: David Zhao

Phone: 15617899999

Tel: 0371-64110451

Email: tigeryc1986@126.com

Add: Group 4,Beiwan Village,Beishankou Town,Gongyi District,Zhengzhou City,Henan Province,China